개요&공정소개

청정에너지로 더 푸르게, SK인천석유화학이 선도하겠습니다

SK인천석유화학은 ‘고객감동과 품질 우선’의 경영이념을 바탕으로 안전하고 우수한 성능을 지닌 제품을 생산하며 시장을 활발히 개척하고 있습니다.

앞으로도 석유 제품의 품질을 향상시키기 위해 생산 설비 개선, 정제공정 정밀화 및 선진 기술 개발 등에 주력할 것입니다.

앞으로도 석유 제품의 품질을 향상시키기 위해 생산 설비 개선, 정제공정 정밀화 및 선진 기술 개발 등에 주력할 것입니다.

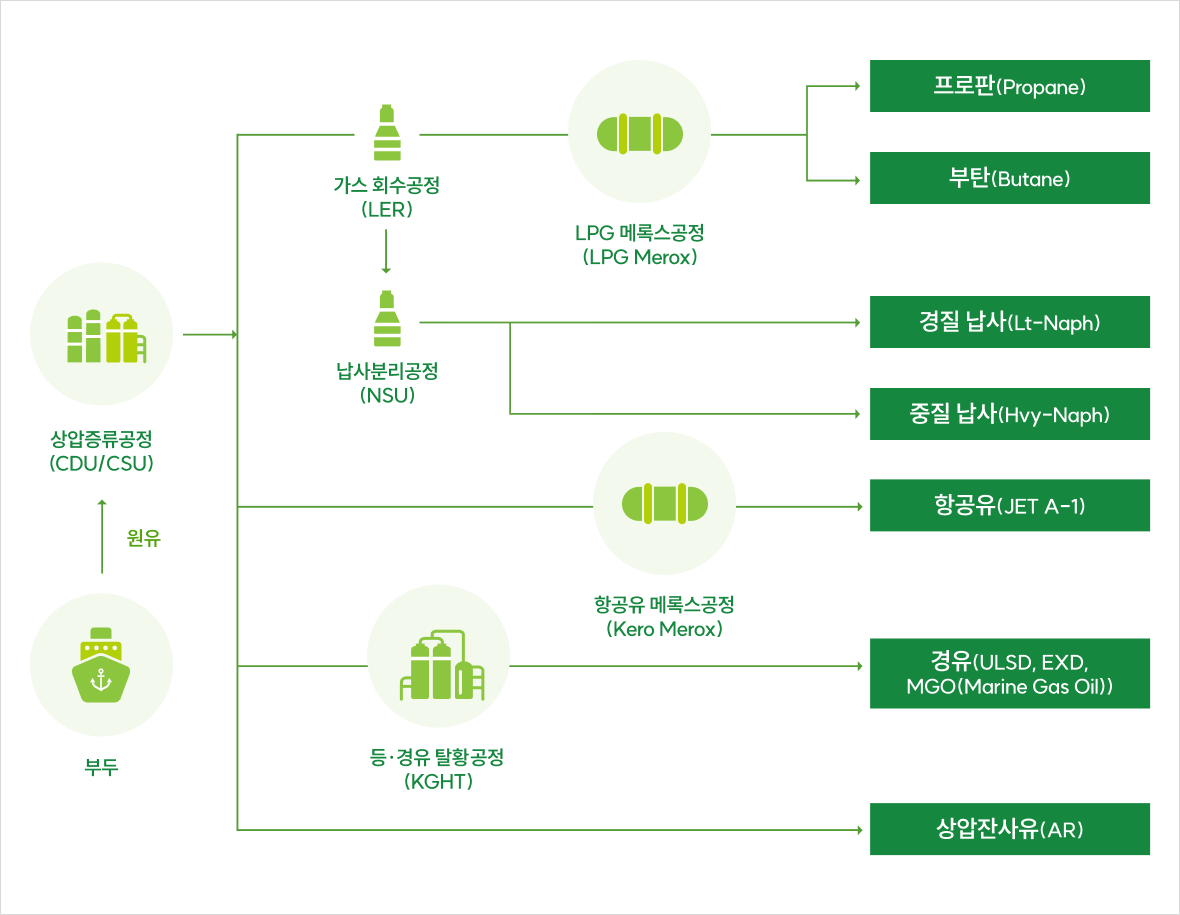

석유공정

- 부두(원유) -> 상압증류공정(CDU/CSU) -> 가스회수공정(LER) -> LPG메록스공정(LPG Merox) -> 프로판(Propane), 부탄(Butane)

- 부두(원유) -> 상압증류공정(CDU/CSU) -> 가스회수공정(LER) -> 납사분리공정(NSU) -> 경질 납사(Lt-Naph), 중질 납사(Hvy-Naph)

- 부두(원유) -> 상압증류공정(CDU/CSU) -> 항공유메록스공정 (Kero Merox) -> 항공유(JET A-1)

- 부두(원유) -> 상압증류공정(CDU/CSU) -> 등경유탈황공정(KGHT) -> 경유(ULSD, EXD, MGO(Marine Gas Oil))

- 부두(원유) -> 상압증류공정(CDU/CSU) -> 상압잔사유(AR)

-

상압증류공정

원유 중에 포함된 다양한 탄화수소 물질을

비등점(Boiling Point)의 차이에 따라 분리 -

가스회수공정

상압증류공정에서 분리된 납사에서

가스 성분을 분리하여 프로판과 부탄을 생산 -

LPG메록스공정

가스회수공정에서 생산된 LPG에서

황 성분을 제거하여 제품 Spec. 준수 -

납사분리공정

비중이 가벼운 경질 납사와 무거운 중질 납사를

끓는점의 차이를 이용해 분리 -

항공유메록스공정

상압증류공정에서 분리된 등유 중 독특한 냄새와 부식을

발생시키는 머켑탄을 제거, 항공유의 제품 Spec. 준수 -

등·경유탈황공정

상압증류공정에서 분리된 등·경유에서 황 성분을

제거하여 품질 향상