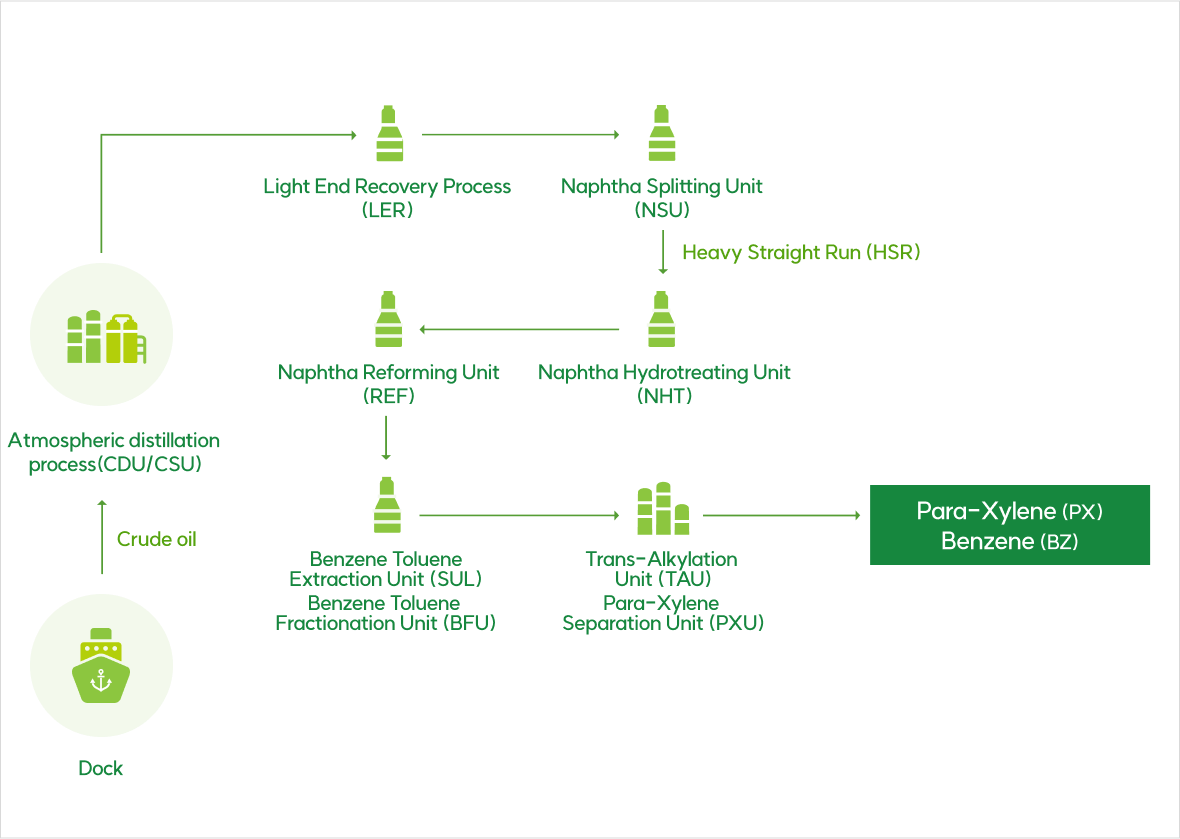

Overview & Process

-

Naphtha Hydrotreating Unit

Removes the sulfur components of heavy naphtha separated in the naphtha splitter process

-

Naphtha Reforming Unit

Reacts desulfurized heavy naphtha with a platinum catalyst to produce aromatics and hydrogen

-

Benzene Toluene Extraction Unit

Selectively extracts high-value-added materials such as benzene, toluene and mixed xylenes using specialized solvents with excellent chemical properties

-

Benzene Toluene Fractionation Unit

Separates benzene, toluene, and mixed xylenes, which are aromatic substances extracted through the BTX extraction process, by fractional distillation

-

Trans-Alkylation Unit

Reacts toluene separated by the BTX extraction process with a catalyst to convert it to benzene and mixed xylenes

-

Para-Xylene Separation Unit

Separates para-xylene from mixed xylene using the principle of adsorption rather than fractional distillation, which uses differences in boiling points